In the fast-evolving world of the Internet of Things (IoT), compactness and performance go hand in hand. As consumer demand grows for smaller, smarter, and more efficient devices, Surface Mount Technology (SMT) has become the go-to solution for IoT hardware design and manufacturing. But how exactly does SMT support the IoT revolution without sacrificing quality?

In this article, we explore the benefits of SMT for IoT, how it enables miniaturization, and why it ensures long-term device reliability.

What Is SMT (Surface Mount Technology)?

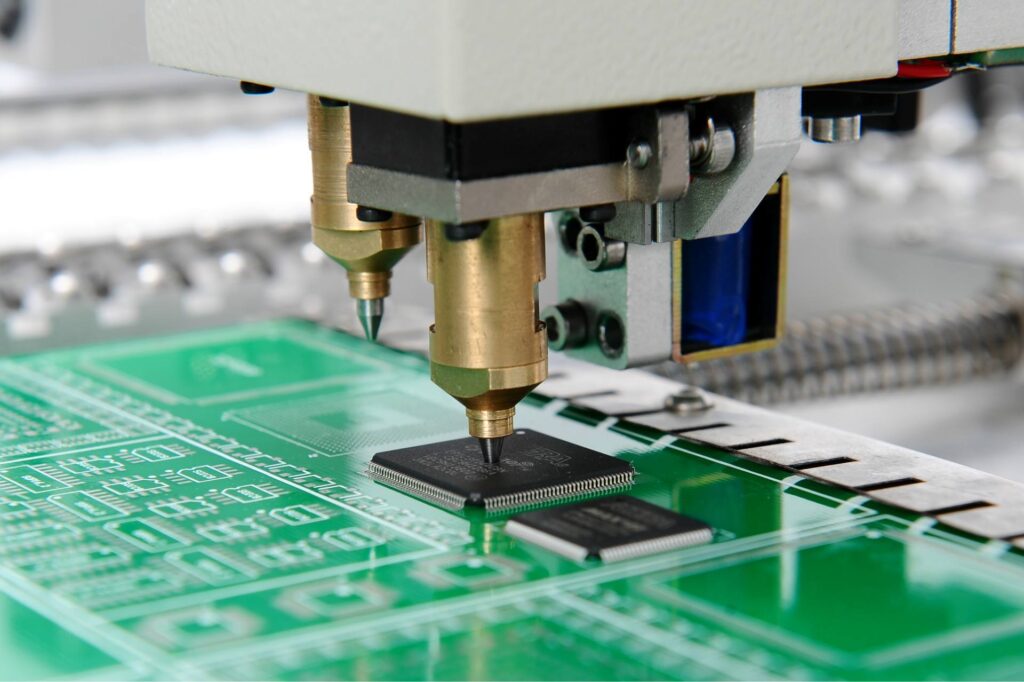

Surface Mount Technology is a method for producing electronic circuits in which components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole techniques, SMT allows for much smaller components and higher component density — ideal for space-constrained applications like wearable tech, smart sensors, and other IoT devices.

Why SMT is Critical for IoT Devices

1. Miniaturization Without Compromise

One of the most important trends in IoT is the shift toward ultra-compact form factors. Whether it’s a smart thermostat, a fitness tracker, or an industrial sensor, the need for small size is universal. SMT enables this by:

- Allowing the use of ultra-small components (e.g., 0201, 01005 packages)

- Supporting double-sided PCB assembly for higher component density

- Eliminating the need for bulky leads and pins

2. Enhanced Performance

Compact doesn’t mean underpowered. SMT components often provide better electrical performance due to shorter interconnects and reduced parasitic effects. This leads to faster signal transmission, lower inductance, and improved overall efficiency—crucial for real-time data transmission in IoT.

3. Reliable Automation and High Production Yields

SMT supports fully automated assembly processes, which significantly reduces human error and improves consistency. For IoT applications that require mass production—like smart home devices or asset trackers—this automation ensures:

- Faster time to market

- Lower manufacturing costs

- Consistent quality control

Quality Assurance in SMT for IoT

With devices often deployed in critical or remote environments, quality is non-negotiable. Here’s how SMT maintains the high standards needed:

- Advanced Inspection Systems: SMT lines use AOI (Automated Optical Inspection), SPI (Solder Paste Inspection), and X-ray machines to detect microscopic defects.

- Reliable Solder Joints: Proper reflow soldering techniques ensure long-lasting, vibration-resistant joints—essential for wearables and mobile IoT.

- IPC Standards Compliance: Manufacturers adhere to IPC-A-610 or similar industry standards to guarantee assembly quality.

Common SMT Components Used in IoT Devices

- Microcontrollers (MCUs): The brains of IoT devices, often in QFN or BGA packages.

- Sensors: Temperature, humidity, motion, and more—most now come in SMT-compatible sizes.

- Wireless Modules: Wi-Fi, Bluetooth, LoRa, and Zigbee modules are surface-mountable, supporting compact, connected designs.

- Power Management ICs: Efficiently regulate power within small devices, critical for battery-powered IoT.

SMT Design Tips for IoT Engineers

- Prioritize component placement for heat dissipation and signal integrity.

- Use multi-layer PCBs to optimize routing in tight spaces.

- Design for manufacturability (DFM) to streamline the SMT process and reduce rework.

Final Thoughts: The Future of SMT and IoT

As IoT continues to expand into every facet of modern life—from smart cities to remote healthcare—SMT will remain the backbone of compact, high-performance electronics. Manufacturers and designers embracing SMT not only benefit from efficient assembly but also ensure that their devices meet today’s rigorous quality and reliability standards.

If you’re developing IoT hardware, integrating SMT into your design and manufacturing process isn’t just a smart choice—it’s a strategic necessity.