In the glove industry, gauge is one of the most important technical specifications, yet it is often misunderstood by end users. Whether gloves are used in industrial environments, medical facilities, laboratories, or everyday tasks, gauge plays a critical role in determining strength, flexibility, and comfort. Understanding how gauge works helps buyers and users choose the right glove for specific applications, balancing protection and usability.

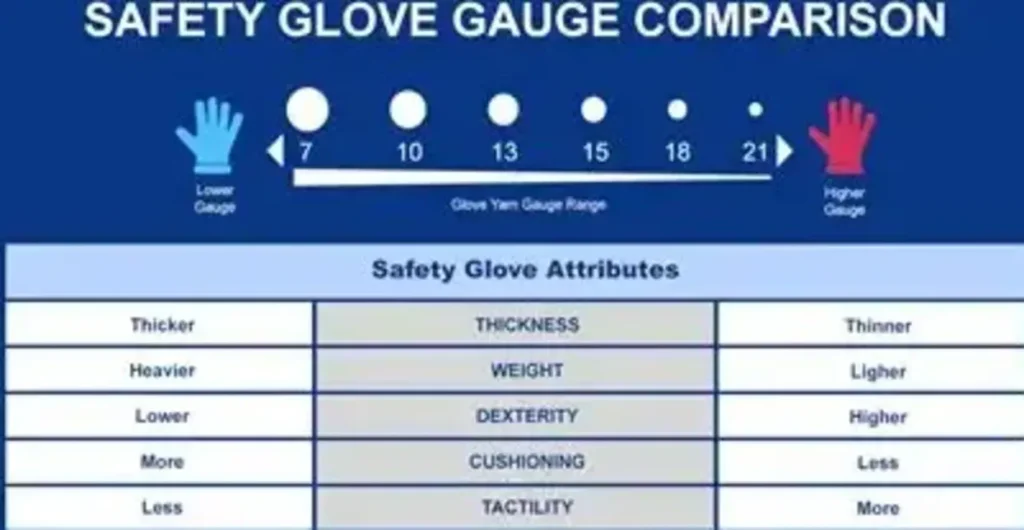

In simple terms, glove gauge refers to the thickness of the glove material. A lower gauge number generally indicates a thicker glove, while a higher gauge number means a thinner glove. This measurement directly influences how a glove performs under different working conditions.

Understanding Glove Gauge

Gauge is typically measured in mils (for disposable gloves) or as a numeric gauge rating (for knitted or coated gloves). For example, disposable nitrile or latex gloves may range from 3 mils to over 8 mils in thickness. Knitted gloves, on the other hand, often use gauge numbers such as 7-gauge, 13-gauge, or 18-gauge.

Each gauge level is designed to serve a specific purpose. Thicker gloves provide enhanced protection and durability, while thinner gloves offer greater dexterity and tactile sensitivity. Selecting the right gauge depends on the tasks being performed and the level of risk involved.

How Gauge Affects Glove Strength

Strength is one of the primary considerations when selecting gloves for industrial or high-risk environments. Lower-gauge gloves, which are thicker, generally offer higher tensile strength and puncture resistance. These gloves are better suited for tasks involving sharp objects, abrasive surfaces, or heavy mechanical work.

For example, gloves used in construction, automotive repair, metal fabrication, and chemical handling often require a lower gauge to withstand physical stress. Thicker materials reduce the likelihood of tearing or puncturing, providing better hand protection and longer service life.

However, higher strength does not always mean better performance. In tasks that require precision rather than force, excessive thickness can reduce efficiency and increase fatigue.

The Impact of Gauge on Flexibility

Flexibility is closely linked to glove thickness. Higher-gauge gloves, which are thinner, provide greater flexibility and freedom of movement. This makes them ideal for tasks that require fine motor skills, such as assembly work, electronics handling, laboratory procedures, and medical examinations.

Thinner gloves conform more closely to the shape of the hand, allowing natural movement of fingers and wrists. This improved flexibility helps reduce hand strain during prolonged use and increases overall productivity.

In contrast, lower-gauge gloves may feel stiff, especially during extended wear. While they offer superior protection, they can limit movement and reduce efficiency in tasks that require precision. This is why many industries adopt different glove gauges for different job roles within the same facility.

Gauge and User Comfort

Comfort is a key factor in glove performance, particularly for workers who wear gloves for long periods. Gauge directly affects comfort through breathability, weight, and tactile sensitivity.

Higher-gauge gloves are lighter and less restrictive, making them more comfortable for extended use. They allow better airflow, reducing sweat buildup and discomfort. This is especially important in warm environments or in jobs that require continuous glove use.

Lower-gauge gloves, while protective, can feel heavier and warmer. However, advancements in material technology have improved comfort even in thicker gloves by incorporating ergonomic designs, flexible coatings, and breathable liners.

Choosing the correct gauge helps ensure that users are more likely to wear gloves consistently, which is essential for maintaining safety standards.

Balancing Strength, Flexibility, and Comfort

Selecting the ideal glove gauge is about finding the right balance between protection and usability. No single gauge is suitable for all applications. For example:

Low gauge (thicker gloves): Best for heavy-duty industrial work, chemical handling, and mechanical tasks where protection is the priority.

Medium gauge: Offers a balance of durability and flexibility, suitable for general industrial use and maintenance work.

High gauge (thinner gloves): Ideal for precision tasks, medical use, laboratories, and light-duty work where dexterity and comfort are critical.

Understanding the working environment, potential hazards, and task requirements is essential when choosing glove gauge.

Gauge Considerations Across Different Industries

In industrial settings, glove gauge selection is often dictated by safety regulations and risk assessments. Manufacturing and construction sectors typically prioritize strength and durability, while electronics and quality control operations focus on flexibility and sensitivity.

In the medical and healthcare sector, higher-gauge disposable gloves are preferred to ensure comfort, tactile sensitivity, and hygiene. In contrast, cleaning and sanitation tasks may require thicker gloves to protect against chemicals and prolonged exposure to moisture.

Household applications also benefit from gauge awareness. Thicker gloves are suitable for cleaning and gardening, while thinner gloves are ideal for food preparation and light chores.

Conclusion

Gauge is a fundamental factor that determines glove strength, flexibility, and comfort. By understanding how gauge influences performance, users and buyers can make informed decisions that enhance safety, efficiency, and user satisfaction.

Rather than choosing gloves based solely on price or appearance, considering gauge ensures the right level of protection without sacrificing comfort or productivity. In any application, selecting the appropriate glove gauge is a small decision that delivers significant long-term benefits.

This article post by: mitrasaruta.com